Feature Story: Blower Door Testing – Measuring the impact of air infiltration

Recent investigative testing performed by HiH at several buildings demonstrated that up to 50% of building heating requirement was as a result of undesired building air leakage. The studied buildings had an average of 10 air changes per hour (ACH).

The good news: Addressing air leakage is typically one of the lowest cost energy savings strategies available to building owners.

What is airtightness?

Airtightness testing is a measure of air leakage and infiltration through a building envelope. Typical infiltration points include window and door frames, electrical and pipe penetrations, and structural joints. In reality, all buildings leak, some a lot more than others.

Why is airtightness important?

In colder climates, a significant portion of building energy consumption is attributed to heating. As more outdoor air enters a building, so does the requirement to heat this air, resulting in increased energy consumption and costs.

What does the Code say?

For new construction projects, the BC Energy Step Code requires blower door testing for all part 3 and Part 9 buildings. Part 9 buildings must achieve an airtightness value of less than 3.0 air changes per hour (ACH) under Step 2. For Step 5, (Net Zero Energy ready) this requirement is reduced to less than 1.0 air changes per hour (ACH).

What strategies improve airtightness?

- Taping and filling excessive gaps in the building envelope, especially at penetration points.

- Installing properly sized door sweeps and weather stripping around exterior doors.

- Detailing of the air barrier during the building design stage.

- Using good quality materials, including membranes, tapes, sealants and fenestration.

- Ensuring that all trades understand their impact on building airtightness.

Blower Door Testing

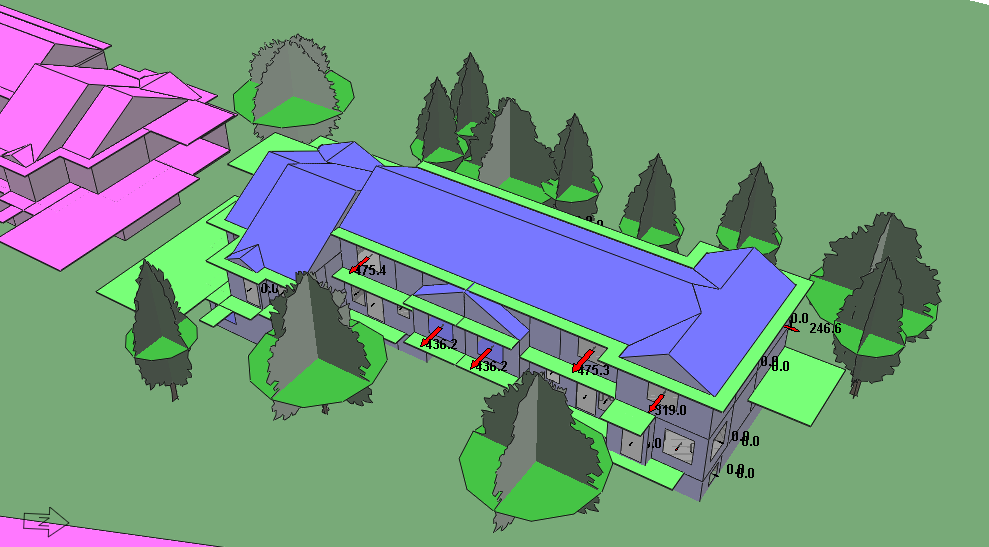

Blower door testing is a simple method of measuring air leakage from a building. The study building is sealed and negatively pressurized to measure infiltration. Smoke pens are used to quickly identify areas of concern. Thermal imaging is also used to detect areas of heat loss, which can be indication of excessive infiltration.

Added benefits of improved airtightness include noise isolation, and a reduction in cross ventilation between units, which is particularly beneficial if your neighbor is a bad cook.

Our Energy Operations Services

HiH Energy is excited to support our clients and partners to create more efficient and comfortable buildings through our energy operations services.

| Blower Door Testing | Pressurize your building, find the major leakage points and report the results |

| Thermal Imaging & Smoke Testing | Identify temperature differences and air leakage points to identify areas of heat loss. |

| Auditing & Training | Develop measures to improve airtightness and predict energy savings and provide air barrier education to your construction team |

| Implement & Verify | After you’ve sealed targeted areas and reduced air leakage, we provide final blower door testing and quantify savings. |

Feel free to reach out to us if you’d like to learn more about airtightness or blower door testing. We are always happy to discuss cutting edge strategies!