The Decarbonization of Building Ventilation

- Installation of heat pump ventilation units can greatly reduce building’s carbon emissions

- Air source heat pump ventilation units are ideally suited to the Vancouver climate

- It is important to validate existing electrical and structural capacities

- Incentive funding from CleanBC will support your business case

Electrification of Ventilation Systems

The provision of ventilation air for buildings, using rooftop and makeup air units, forms a significant portion of overall building energy demand and carbon emissions. This is particularly true when older, less efficient equipment is involved.

Multi-unit residential buildings (MURBs) for example typically incorporate natural gas fired make-up air (MUA) units to provide corridor pressurization & ventilation.

We often find that these makeup air units are low cost models, which deliver constant air volume at a constant supply air temperature.

Is there a better way of providing building ventilation, that results in reduced energy consumption and carbon emissions?

Advancements with Heat Pump Technology

New generation air source heat pump ventilation systems, including rooftop units (RTU) and makeup air units (MUA), offer a highly efficient method of heating ventilation air, while eliminating carbon emissions from burning natural gas.

Standard efficiency natural gas heated ventilation units typically operate with a combustion efficiency of less than 80% (factoring in degradation over time).

Heat pump ventilation units can provide effective heating of ventilation air for most of the year in Vancouver. Units with a coefficient of performance (COP) of around 3.5 are typical.

Our experience has shown that heat pump MUAs typically require auxiliary heating for the fraction of the year when outdoor air temperatures are at or below freezing (typically 5% of the time in our climate). Redundancy is typically provided in the form of electric resistance or natural gas heating backup.

Due to the “plug and play” replacement technology options, ventilation systems are commonly regarded as one of the easiest mechanical system to electrify from both a technical and financial standpoint.

Operational Improvements

Compared to conventional natural gas units, heat pump MUAs offer several benefits beyond reduced GHG emissions:

- Improved energy efficiency and reduced operating costs

- Option to provide cooling is especially valuable with rising temperatures

- Enhanced control and higher precision of heating/cooling for improved comfort

- Wider range of compatible airflow rates for future adjustability and resiliency

Design Considerations

The following should be considered as part of the design process when specifying heat pump ventilation units:

- Electrical – Does your building have sufficient electrical capacity available to support the additional load? Fortunately, we have found that most buildings can.

- Structural – Heat pump MUAs are typically heavier than their simple gas only counterparts. Therefore, structural upgrades and associated permitting may be required.

- Sound & vibration – Heat pumps incorporate compressors that are constantly responding to heating/cooling demand. Adequate vibration isolation should be included by the manufacturer and in design.

Recent Case Study

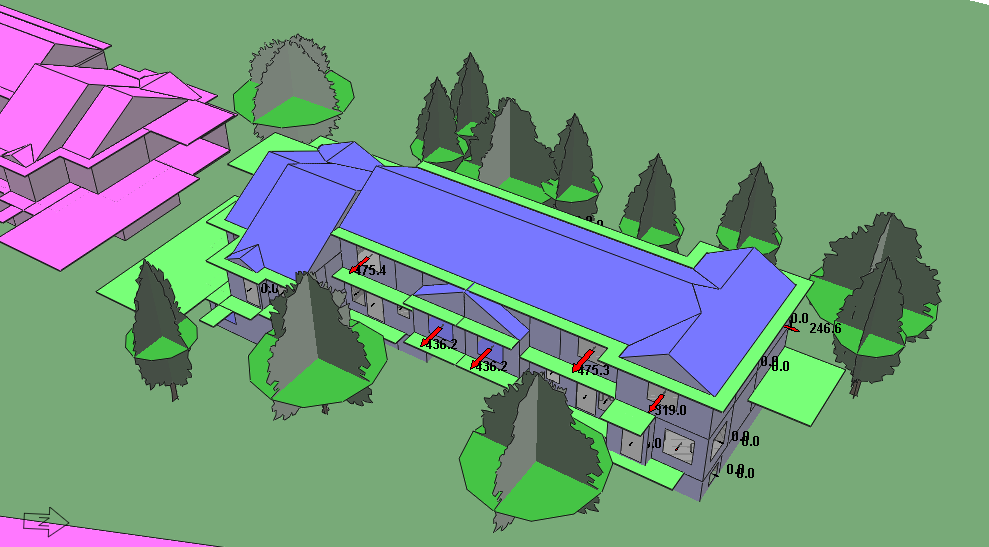

The above photo features the recent installation of a hybrid heat pump make-up air unit at a MURB in Vancouver. Before the install, ventilation gas usage was calculated at over 40% of the total on-site natural gas consumption – purely for tempering ventilation air to the corridors.

The project involved fuel switching this equipment with the intent of achieving substantial GHG reductions while capitalizing on available incentives and ongoing energy savings.

By metering the existing electrical demand, we were able to determine that sufficient electrical capacity was available to support a right-sized heat pump MUA unit. The unit incorporated back-up natural gas heating for below freezing outdoor air temperatures, a variable frequency drive (VFD) on the supply fan, and a variable capacity compressor for optimal heat pump modulation and efficiency.

With some structural considerations and additional measures to mitigate vibration, the unit was successfully commissioned and is now operating smoothly with the new benefit of cooling for peak summer temperatures. Now it is time to sit back and wait for the lower utility bills.

Incentive Funding

CleanBC Better Buildings incentive program offers up to $60/tCO2e offset over the equipment lifespan. This is increased to $70/tCO2e for social housing projects(SHRSP).

If you would like to learn more about heat pump ventilation units or the applicable incentive programs, feel free to reach out to our team!

Steve Fetterly, P.Eng

Lead Energy Engineer